When different designers, businesses, as well as engineers consider product development, most of them look at prototyping coupled with mass production as the primary goal and objective. But there are certainly moments when low-volume manufacturing is an optimal choice for people who demand modest quantities of parts, ranging from hundreds to thousands. In this blog post, we major our discussion on the low volume manufacturing strategies with a careful analysis of the nature of low volume production.

When utilizing a prototyping manufacturing service such as 3ERP, customers can gain the capability to increase the number of products and parts they need, regardless of the look of the final outcome.

Background Check

Low volume production implies different things to a variety of people. Being experts, it translates into the delivery of different quantities (typically less than 1,000 units per month). But this is just a comprehensive guideline.

It all depends on the size of the parts, the geometry, coupled with additional factors therein. If the production department exceeds 1,000 units every month, it would be advisable to consider various processes that can be cost-effective.

Why Low Volume Production?

Typically, low volume production serves the following purposes:

- The replacement of parts is not available in the production process. These are usually parts needed for repair

- Low-volume production elements are often parts created after the prototype phase is complete. These parts are also known as the production parts. Basically, they are tools for refurbishment.

- The low-volume production elements are created typically created after the phase of prototype design.

- They offer a considerable bridge between a prototype phase as well as the high-volume phase, where usually, different parts shall be manufactured using hard tooling. On that note, some manufacturers refer to the elements as the pre-production parts.

In the world of plastic manufacturing, we have exhibited our ability to utilize low volume production at trade shows all over the country. We have also had the chance and privilege to meet customers who have visited our shop to inquire about the services we offer.

When we offer an explanation about building and producing prototypes and production tooling, coupled with the manufacture of low volume production parts, one of the most commonly asked question is what quantity exactly does our team consider low volume?

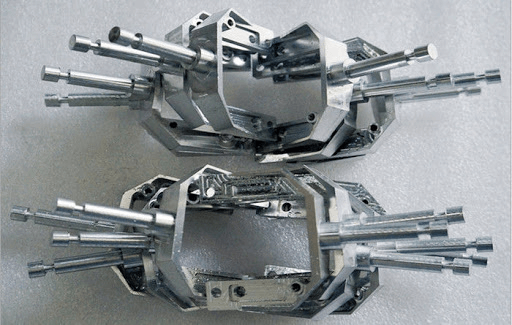

An easy and direct answer has always been under 100,000 units annually. But in the real sense, it really just depends. In many instances, customers approach us to develop high-quality production prototypes. Through utilizing the modular tooling system, consumers can grasp an added advantage of the affordable tooling prices. Immediately prototyping is done, some customers need an estimate of about 10,000 production parts.

Final Thoughts

Our offer on low production volume has been providing an ideal solution for clients with different needs. Some start-ups happen to be searching for a cheap and low-risk method of introducing their products into the market. On the other hand, others are known for being million-dollar firms that need low yearly quantities of specialty as well as replacement parts.