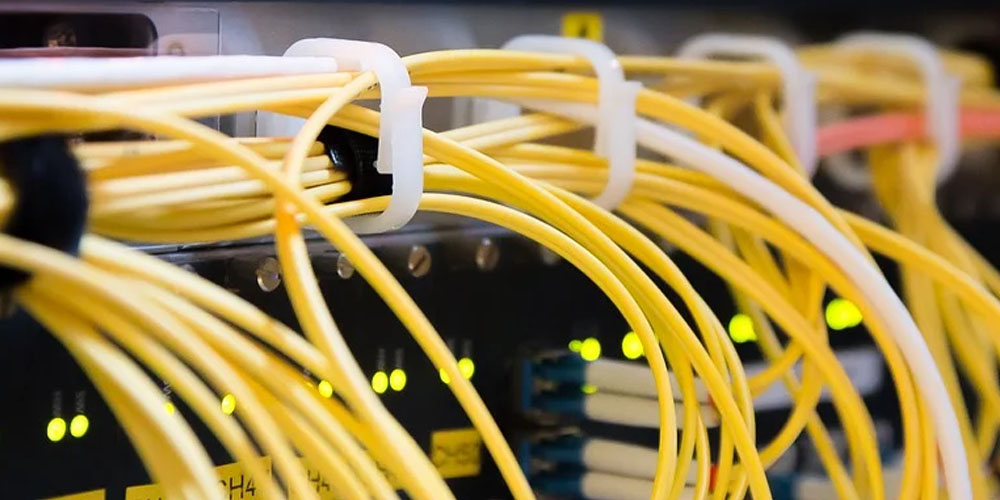

LAN for high-density server systems, the Local Network Cable is indeed the ideal option. Whenever it concerns technology and application connectivity requirements, you will never go wrong with Cable Network devices. LAN Cable manufacturers, export distributors.

If you want superior speed, efficiency, and dependability, It represents a wider variety of Local area network cables, comprising Ethernet cable, short Ethernet jack, optical fiber, telecommunications wire, and wired network LAN connector cable. The LAN connections come in various lengths, colors, and volumes, and patched formats.

LAN provides the finest quality and best performance, along with after-sales support, to assist you in achieving greater Over a hundred kilometers; our widely used Core layer can provide transport speeds up to 300mbps with such a frequency band of 500Mhz. In addition, users can visually Livestream and engage in videoconferences.

Benefits of LAN:

A local area cable network’s primary purpose is distributing; it’s apparent that somehow this type of connection provides considerably quicker interaction. Not many documents, as well as other information, are exchanged significantly quicker within the local area network instead of just requiring to go beyond the web beforehand, but a moment in time connectivity could also be established even for rapid official management.

LAN Cable Manufacture Process:

The in-house connection production process produces the absolute best specialty LAN Connectors for technology and application connectivity.

Step 1

A Sequence of Cable Processing Techniques Increases Cord Width, the Very First Wire Draw.

Wire designing seems to be the preliminary step in constructing Ethernet wires. Wire drawing is indeed a means of reducing the thickness of a cable while simultaneously extending its height by dragging this through a machine. Its size is still the same as just a consequence of it now.

The deaths are filled with fluid which also functions as just a reservoir, extending the life of the ends and eliminating heating of both the electrical cables.2nd Wire Draw

The circuit breaker created throughout the first drawing would then be transported to that of an insulator area of the plant, where it would be exposed to a secondary cable draw, followed by annealing before being insulated.

In the second wire draw, the copper is decreased in thickness to 19, 22, 24, 26AWG, or any size required.

Step 2

Equilibration the Cable Lightens the Cable to produce copper cable bendable, it should be warmed from its own hard condition following drafting. Welding seems to be the method of applying copper to a constant temperature and afterward reducing it gradually.

The cable which has been submerged is warmed over 1000 Fahrenheit for such a short period of time before even being withdrawn from the water. This copper is preserved from corrosion and oxidation by simply submerging that in liquids.

Step 3

Bending and Bonding of Cable

Each cable should then be pushed through to a compressor, in which a simple or even double coating of the protective cover is placed. Particles of increased polymer are introduced into the compressor.

Step 4

Wire Thickness and Insulator Testing

Cable & insulator thicknesses are determined, as well as the wire is checked for electromagnetic parameters, including such inductance and susceptibility even before loops proceed onto another product shows.

Step 5

Trying to twist and Tying up the Cable.

The insulation cables are wrapped from connected to the idea throughout this step. To prevent interference and disturbance, every pair does have its own rotation duration.

Electromagnetic problems such as bridges, sparks, and holes will now be inspected on the cables.

Step 6

Wiring

The conductors which originated from either the trapping procedure are joined together at the same point to generate inter cable cores. To further minimize electromagnetic meddling and give flexibility, these modules are screwed together on the same revolving inner carriage.

Step 7

Jacketing

Many operations are carried at soldered joints that create the finalized cables, comprising silicone, armor kits, soldered joints, and imprinting.

To summarise, LAN is the fastest network. You can never go wrong with LAN Cable for your network.