The popularity of roll-up garage doors in residential and commercial settings can be explained by the fact that they occupy less space, are robust, and do not require much effort to operate. Such doors have torsion springs in the middle of the door, and the weight of the door is supported by the springs, hence swinging easily. But over time, springs may be corroded by the effects of environmental conditions such as moisture, dust, and changes in temperature, and this may impair the service and life of springs. Corrosion prevention of roll up garage door springs is hence critical in the provision of reliable operation and extended life of the springs.

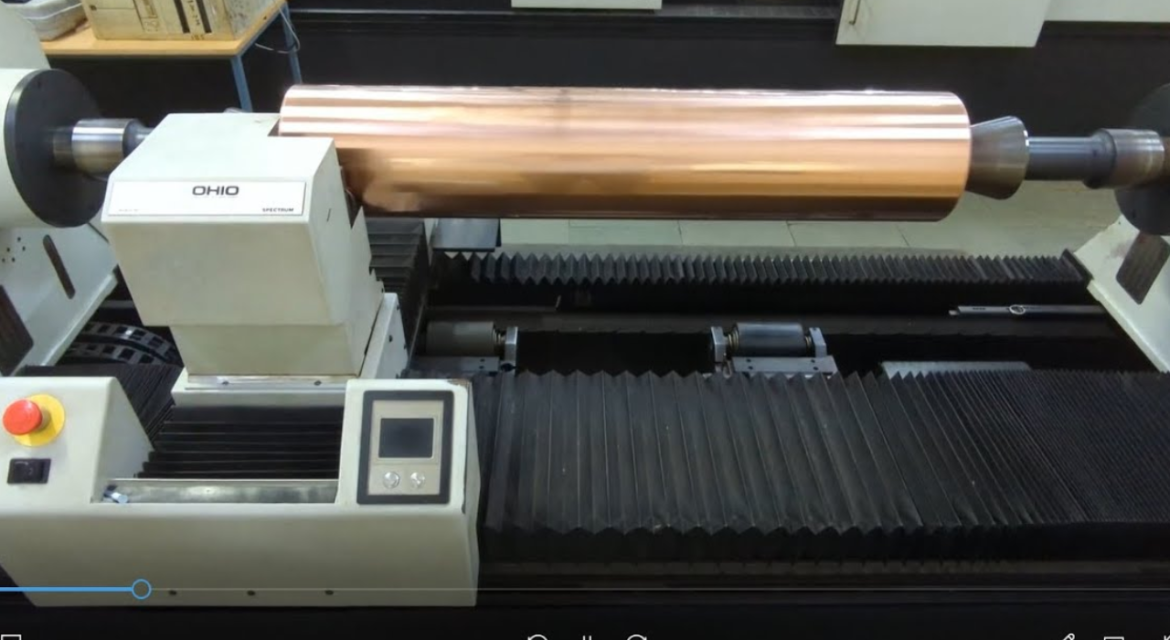

Knowing Roll Up Garage Door Springs

This system enables the heavy doors to move freely, and the lifting hardware and the motor do not strain. These springs are usually made of high-tensile steel, such as ASTM A229 Class II oil-tempered wire, a product that is strong and can last through repeated applications. Although they are strongly built, corrosion may be experienced in case of failure to take relevant precautions, resulting in weakened springs, unbalanced door opening, or possible safety risks.

Lubrication as a Corrosion Prevention

Lubricating the spring is one of the best methods of stopping corrosion. Lubricated springs are produced by means of a protective coating of the springs in factories with high-quality oils, and this protective coating helps to minimize friction and protect the metal against moisture. This coating, which is applied to stop the rusting of the coils, is reliable and gives the coils a high number of cycles before they stop operating. In springs that are not lubricated in the factory, appropriate lubricants should be applied regularly. A lubricant with a specific application to garage door springs forms a protective cover against the effects of the environment and decreases the wear of metals rubbing together.

Managing Environmental Exposure

Environmental conditions have a considerable influence on the development of corrosion. Roll-up garage doors placed in a humid environment, where a lot of rain is experienced, or even where they are exposed to the sea, are especially prone to rust. It is through reducing these environmental risks that the prevention of corrosion can start. Reduction of exposure to moisture can be done through installing the door in a sheltered area or by placing the weather seals and protective shields. Washing the door and springs regularly to get rid of dust, dirt, and debris also aids in making sure that no excessive moisture remains on the metal surface, thus reducing the risk of rusting.

Working with Quality Materials

The spring itself is made of a material that plays a significant role in corrosion resistance. Torsion springs that are of high-quality, manufactured using oil-tempered steel, will not easily corrode as compared to untreated or low-grade steel springs. Protective coatings or finishes on some springs, like zinc plating, are also added to offer an extra layer of corrosion resistance. When selecting springs, one needs to select those manufactured by a well-known company in terms of being of international standard in terms of durability and corrosion resistance, providing long-term reliability to both residential and commercial garage doors.

Periodic Servicing and Check-Up

Regular maintenance is necessary to detect the initial cause of corrosion and take corrective measures before the situation deteriorates. An occasional check will enable the user to identify rust, discoloration, or other indications of spring wear on the surface. The dirt, moisture, and corrosion of a minor nature must be dealt with as soon as possible by cleaning the spring and oiling it with a suitable lubricant. Routine maintenance helps not only in avoiding corrosion but also in the smooth running of the machinery, and the chances of spring failure occurring unexpectedly are minimized, which is hazardous and expensive.

Corrosion Management: Professional Help

It is very risky to use roll-up garage door springs without knowledge and the appropriate equipment, as they are under high tension. Any effort by any individual to clean, lubricate, or replace springs will lead to injury or destruction of the door system unless the work is done by a professional. Regular maintenance and lubrication done by certified garage door technicians should ensure that the methods of corrosion prevention are implemented safely and efficiently. It is also possible that professionals may suggest the most appropriate lubricants and protective paint depending on the environmental conditions of the place of installation.

Conclusion

The garage door roll-up door springs are very important to the safety and efficiency of the garage door, but they are likely to be affected by corrosion unless they are coated in an appropriate way. The issues of corrosion may be prevented successfully with the assistance of factory lubrication, environmental control, the use of high-quality materials, continuous maintenance, and professional assistance. These measures will guarantee the springs to be long-lasting, dependable, and able to offer smooth door opening and operating for many years.