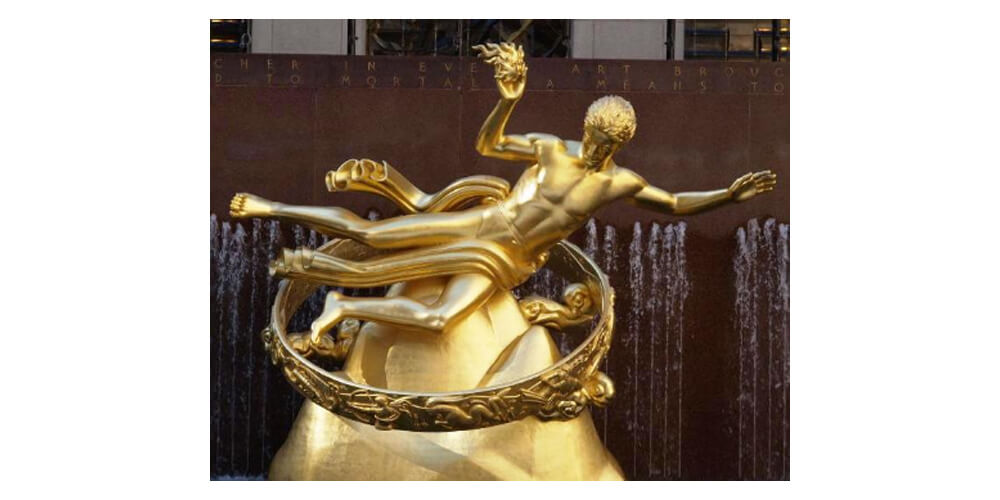

One of the common traits of many successful businesses is that they like to be surrounded by art. Sometimes it is a massive collection, other times it is one or just a few pieces.

Bronze sculptures are in demand as much as art paintings. More and more businesses and startups invest in bronze sculptures. Some opt for modern ones, while others prefer classic bronze sculptures. The good news is that there is no shortage of bronze sculptures for sale, both modern and classic sculptures.

Why bronze sculptures are popular? What makes them so appealing to businesses in 2020? Here are the top five reasons why many businesses buy bronze sculptures.

#1 It’s timeless

For thousands of years, bronze sculptures represent wealth, social status, style, and success. From Roman emperors to filthy rich business people, bronze sculptures represented the magnitude of their success.

Nowadays, even startups try to convey that image, even though they haven’t made their impact yet. They love the idea of it as the bronze sculpture within their property or premises conveys a message.

#2 It’s an investment

Many people fail to understand that good art is like a good real estate property whose price increases with time, especially if it comes from a talented sculptor. Years later, the sculpture may be a worth couple of times more than its original value.

#3 It’s timeless

It’s pretty much timeless and can last for centuries. It can be the perfect medium that can tell the humble beginnings of a company and its rise to greatness. CEOs and founders like the idea of leaving something behind, something that will speak on their behalf and their legacy.

#4 Easy maintenance

This is also a thing for many companies. The fact that bronze sculptures are low maintenance means that one doesn’t devote a lot of resources for their maintenance. Typically, there is no need to hire additional crew or specialist for the maintenance tasks as that can be done by the same employees that clean the premises.

#5 It’s the perfect medium for both modern and classical sculptures

Whether you want a classic or a modern type of bronze sculpture, you can have it. There are as much as classical as there are modern bronze sculptures. There is a small army of artists that love working with bronze.

#6 Many famous artists created timeless masterpieces with bronze

Auguste Rodin, Henry Moore, and Donatello have changed the world of art with their bronze sculptures. Their sculptures are worth hundreds of millions of dollars. Business people love the idea of buying a bronze sculpture from the next Henry Moore or Rodin.

#7 Companies buy bronze sculptures because they can

This sounds like a bit arrogant, but it is a legitimate factor. Again, it is all about sending the right message to potential business partners, clients, investors, and employees. Bronze sculptures are expensive and everyone knows that. Owning a bronze sculpture says that you are solvent and that the business is doing great. In the business world, that is often super-important, especially with startups.