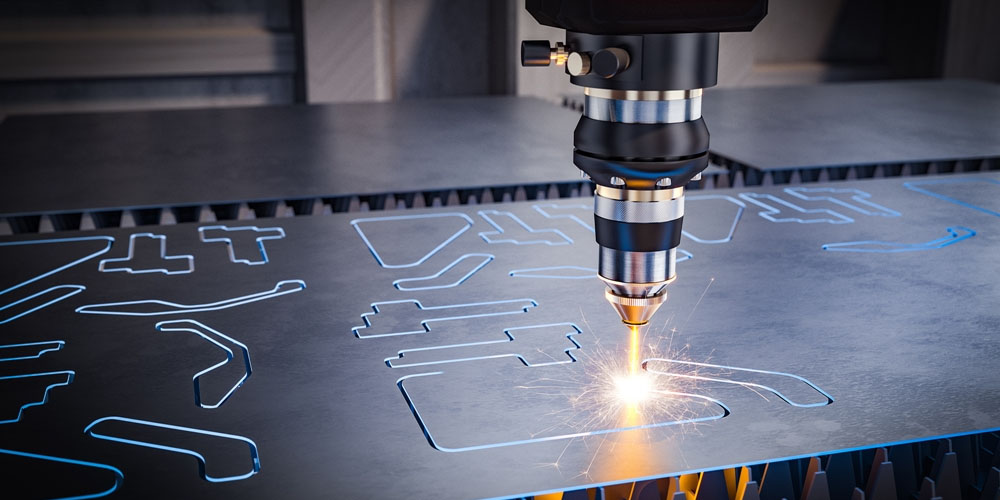

CNC manufacturing remains the secure cornerstone of the manufacturing industry, consistently growing and enhancing manufacturing processes and capabilities. CNC manufacturing must entail high-quality products, excellent types of equipment, superior customer satisfaction, and attention to the emerging and most recent manufacturing technologies to satisfy the industry’s increasing demands. Today, CNC manufacturing offers the highest wavering, reliable, and high-quality machining services. Go here for more about the basics in detail.

The applicable CNC manufacturing industries are automobile, optics, aerospace, electronics, education, robot, and medical.

CNC Manufacturing Components

1.CNC Milling Service

It provides WEDM, EDM, surface grinding, and CNC turning. Sophisticated 5-axis, 3-axis machining centers united with other sophisticated functions, and a team of experts deals with all the technicalities of creating parts and prototypes.

2.Prototype Machining

It offers various prototype machining abilities, including WIRE EDM, EDM, and the 5-axis CNC machining. Quickly manufactures components and parts to examine conceptual models within the domain of specifications.

3.CNC Turning Service

Precision CNC turning provides accurate and quality service to ensure that each part manufactured meets requirements and exceeds expectations while improving the process by adding technology and advanced equipment.

4.CNC prototyping

Makes the most complicated geometrical shapes of prototypes and turns your concepts into reality using high-quality CNC milling machines to achieve any form.

5.EDM Machining

It provides accurate, EDM machining services. EDM is used for machining portions with complicated shapes of holes, dies, and cavities, machining different brittle and hard materials like quenched steel and carbide; deep pickles, narrow slices, forming tools, deep grooves, and processing other screw ring gauge tools.

6. 5 Axis CNC Machining

Takes ultra-precision of 5-axis CNC machining to lower the delivery cycle and costs. The focus is mostly on 5-axis synchronous CNC machining outline and machining positioning that requires a precision machine to perform.

7.Wire EDM

High-quality wire EDM machining produces precision components with tolerances within and outside of your design size. Advanced programming and advanced EDM equipment make the most complicated parts with perfect repeatability and accuracy, whether you require low volume manufacturing, rapid prototyping, or mass production.

8.Production Supply

Production and manufacturing supply services must ensure that bulk production of parts complies wholly with specifications and design intentions. When faced with mass manufacturing of products and a need to narrow the production cycle sooner, you can finish the challenging tasks given limited production time.

9.Design Verification

CNC manufacturing completely understands the significance of verifying prototype design in time to market and optimizing new products. It helps consumers launch products with complicated structures; provide fundamental engineering analysis, manufacturing optimization, and technology to accomplish customer goals.

10.Global Sourcing

This medium is an integral part of the whole manufacturing sector. It analyzes global procurement opportunities and contract manufacturing in line with customer objectives and requirements. As a result, consumers make informed choices based on quality, price, capacity, delivery time, and service.

Final Thoughts

CNC manufacturing offers customized machining services to help consumers solve the most elaborate prototype machining needs. An improved CNC machining department has milling, EDM, and turning centers. Whether you have a small project, a large project, a long-term project, or a one-time project, CNC manufacturing provides you with excellent technical services.