Well drilling operations in the oil and gas industry rely heavily on API 5CT N80 steel pipe. The N80 pipe, thanks to its special mechanical and chemical properties, can withstand the pressures of a wide range of well environments without compromising the safety or effectiveness of the drilling process. Let’s look into the uses and benefits of API 5CT N80 Casing and Tubing in the well drilling industry.

An Explanation of the API 5CT N80

When it comes to quality and dependability, API 5CT N80 is the gold standard. This steel pipe variety is produced in accordance with the guidelines established by the American Petroleum Institute (API), and it is designed to fulfill particular mechanical and chemical needs. The ‘N80’ stamp on a pipe means it has passed extreme pressure and temperature tests to guarantee its quality and reliability.

Adaptability to Different Types of Wells

Well drilling is one of API 5CT N80’s most common uses. N80 casing and tubing provide unrivaled wellbore protection, whether onshore or offshore. Its resistance to corrosion and high pressure makes it a good fit for both traditional vertical wells and more complicated horizontal wells.

Wells With Extremely High Pressures And Temperatures

High-pressure, high-temperature (HPHT) well conditions are ideal for API 5CT N80. To survive in such extreme conditions, materials must be strong enough to withstand high temperatures and pressures without breaking down. The high tensile strength and high impact resistance of N80 ensure its superior performance in the harshest of well conditions.

Offshore Drilling Operations

The corrosive nature of seawater and the extreme conditions of the marine environment present special difficulties for offshore drilling. In offshore drilling applications where well integrity must be maintained for safety and operational success, API 5CT N80 is a reliable choice due to its resistance to corrosion and durability.

Reliability and Quality Assurance

The production of API 5CT N80 is subject to rigorous quality assurance testing. This guarantees the pipes are up to code and will function reliably no matter the weather. Products made with this level of care and in accordance with these standards are built to last and can be relied upon without fail.

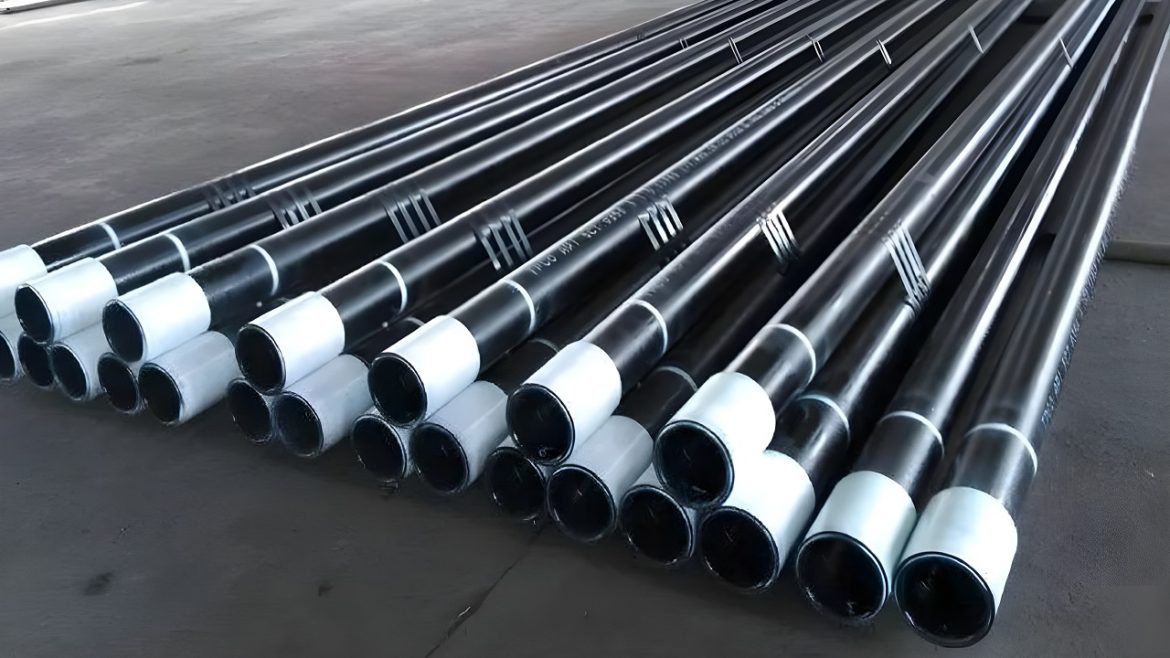

Product Description of API 5CT N80

There is a wide range of outer diameters (OD), wall thicknesses (WT), and lengths (R1, R2, and R3) for API 5CT N80. Plain end, short round thread, long round thread, and buttress thread are all possible options for the end finish. The surface can be black painted, oiled, or left untreated to meet the needs of the customer. It is used in the natural gas and oil industries for transporting gas, water, and oil.

Advantages in Horizontal Wells

Horizontal drilling’s ascent has been game-changing for the oil and gas industry because it has allowed for greater efficiency and opened up hitherto inaccessible reservoirs. The properties of API 5CT N80 make it an excellent choice for use in horizontal wells. Its durability and adaptability to different wellbore geometries are key factors in the success of horizontal drilling.

Conclusion

API 5CT N80 is a prime example of how cutting-edge technology can be used to address specific issues that arise during well drilling. It can be used in high-pressure and high-temperature situations, as well as in horizontal drilling and offshore operations. API 5CT N80 is crucial to the safety, efficiency, and success of well-drilling projects because of its superior mechanical properties, corrosion resistance, and adherence to industry standards. API 5CT N80 is still a dependable and essential part of well drilling operations all over the world, despite the ever-changing oil and gas industry.