In the present cutthroat market, associations are persistently searching for approaches to create adequacy and lower expenses to stay before their adversaries. One effective technique for achieving this is by putting resources into a horizontal plastic injection molding machine. This kind of machine takes into consideration the exact creation of plastic parts, which can extraordinarily help many enterprises.

By getting a horizontal plastic injection machine for your business tasks, you can essentially upgrade your creation capacities and smooth out your assembling processes. Horizontal plastic injection molding machine offers more noteworthy adaptability concerning plan choices, considering the creation of perplexing and unpredictable parts easily.

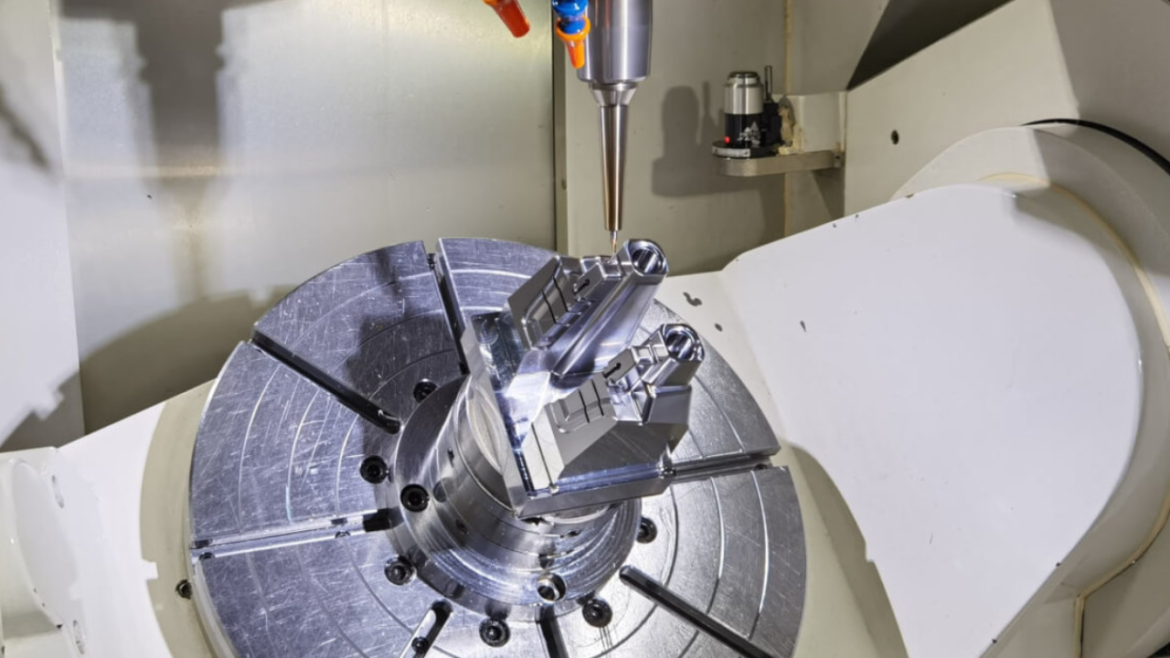

What is the Working Principle of a Horizontal Plastic Injection Machine?

A horizontal plastic injection molding machine stirs by first heating up the plastic sap to a fluid state. The warmed tar is then infused into a shape pit in an even bearing, considering accuracy and exactness in the end result. The form depression is then cooled, hardening the plastic into the ideal shape. This interaction is rehashed for each cycle.

Reasons for Investment in a Horizontal Plastic Injection Machine

Putting investment into a horizontal plastic injection molding machine can fundamentally affect your business in the present quick-moving business sector:

Upgraded Creation Effectiveness

One of the vital advantages of a horizontal plastic injection molding machine is its capacity to smooth out the creation cycle. By wiping out the requirement for physical work and decreasing process durations, these machines can incredibly expand productivity and result. This implies that you can deliver more parts significantly quicker.

Prevalent Item Quality and Consistency

One more benefit of horizontal plastic injection molding machines is their capacity to convey prevalent item quality and consistency. These machines are intended to exactly control each part of the trim cycle, bringing about items that are liberated from deformities and irregularities. This implies that you can convey top-notch items to your clients reliably.

Cost Savings

Horizontal plastic injection molding machines can likewise assist you with saving costs over the long haul. By diminishing waste and streamlining energy effectiveness, these machines can bring down your creation expenses and increase your main concern. Whether it’s by utilizing less material, delivering less flawed parts, or consuming less energy.

Flexibility in Material and Plan Capacities

One more motivation to consider putting investment into a horizontal plastic injection molding machine is the flexibility it offers concerning material and plan capacities. These machines are equipped for working with many plastics and can oblige complex plans with accuracy and precision. This implies that you can create different items to meet the assorted requirements of your clients, assisting you with remaining in front of the opposition.

Versatility for Developing Creation Requests

As your business develops, you want gear that can develop with you. Horizontal plastic injection molding machines are exceptionally adaptable, permitting you to increment the creation limit depending on the situation without settling for less quality or effectiveness. This implies that you can undoubtedly adjust to the changes sought after and extend your tasks without putting resources into a new gear.

Worked on Upper Hand and Market Position

At last, investing in this injection machine can give your business an upper hand on the lookout. By further developing proficiency, quality, and cost investment funds, you can separate yourself from contenders and draw in additional clients to your business. This can assist you with reinforcing your market position, increment benefits, and making long-haul progress in a cutthroat industry.

Sum Up

Investment in a horizontal plastic injection molding machine can be a unique advantage for your business. By upgrading creation proficiency and speed, further developing item quality and consistency, saving expenses, helping flexibility, obliging versatility, and acquiring an upper hand, you can situate your business for progress in the present serious market. So why stand by when you can take your business to a higher level?