The MPO-LC Breakout cable is a useful cable with a lot of economic benefits. The multi-fiber cable helps to upgrade the existing 10G networks to either 40G or 100G. The latter networks are referred to as high performing networks. It is highly sought after by top telecommunications, electronic, and data network companies.

The MPO breakout cable could contain several fibers. There are the 8 fiber, the 12 fiber, and the 24 fiber depending on your preferences.

Functions of the MPO-LC Breakout cable.

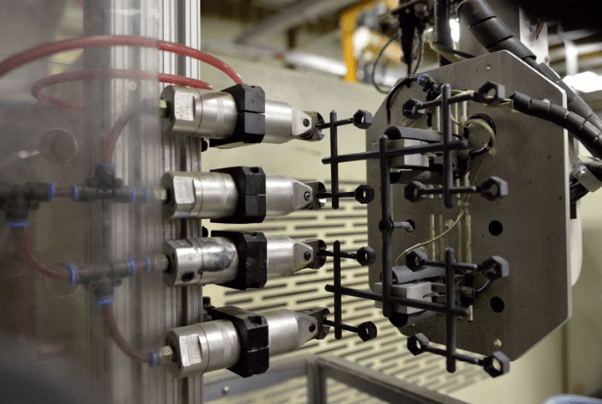

The main function of the MPO-LC breakout cable is to redistribute optical fibers of various specifications to several devices without the inclusion of any additional equipment. In complex network environments, these MPO cables help to reduce the networking cost and time to set up the network.

Large companies often choose to go for this MPO-LC breakout cable because it helps them reduce the additional hardware connected to their servers within short ranges. The unique ability of this MPO-LC fiber is to take fibers from a single source and redistribute it across various sources.

This enables the network to be easily assembled and eliminates the need of getting more expensive networking equipment.

When it comes to fiber networks, the use of Fiber cables helps to reduce the entire complexity of the network, allowing you to save time, energy, and money.

Why Choose FSC?

Getting a good simply means you should be getting an FSG MPO LC Breakout cable. This is because the MPO-LC breakout cable does the job very well when it comes to transmission within short distances

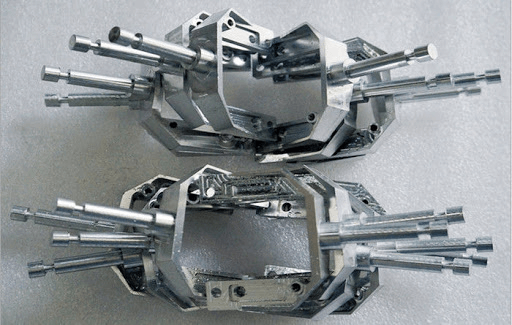

In our company, we try out best to provide you with the best MPO-LC breakout cables that will serve you at all times. TO improve the durability, we can give you the armored jacket for you. This armored jacket consists of a Kevlar and a Steel braid.

The steel braid rests comfortably on the Kevlar tube which makes it protective and prevents any accidents that may occur as a result of it.

Our company has been at the forefront of MPO technology for several years and over these years, we have satisfied a lot of clients worldwide. Our MPO-LC Breakout cable is built to last and the give you the best results in your home, office, or factory.

The MPO Cable from FSG is what you need. It is durable and very efficient to serve you for a long time. Our cables come in various configurations. We have the 8, 12, 24 Fiber and it goes to 144 Fiber for a variety of applications.

CONCLUSION

Over the years, we have done our best to equip our engineers regularly to always give you the best. Our MPO-LC breakout cable beats our competition at all times. Our brand is trusted by millions of companies all over the globe because of our quality of delivery.

We know the importance of these MPO-LC cables that is why we manufacture them to perfection. Visit us today.