We are experts in the plastic injection molding process. As a team, we customize everything to fit into the demands of our customers. We also produce prototypes coupled with end-use production elements in about 20 days or less. Our team of production makes good use of aluminum molds, which provide cost-efficient tooling coupled with accelerated manufacturing cycles as well as other useful stock. What is plastic injection molding manufacturing?

Our plastic injection guidelines will assist you in picking the right materials for your production processes. So why choose this method for your project?

Several proto labs make good use of rapid injection because it is a technology-driven process that highly leverages automation. All too often, in these processes, CAD models are used in the production of vital materials via the milling processes. The molds are then fabricated straight from aluminum. Steel cannot be used in such processes. The entire process allows for the team in charge to enjoy having a faster as well as effective tooling. As experts in charge, we provide additional secondary services which play a great role in supporting your project.

Definition

By definition, the plastic injection molding process refers to the whole technique of melting the plastic. This process is in this case the raw material enough to be able to inject some pressure into the mold cavity, which ends up filling as well as solidifying in order to be able to produce the end product.

How Does It Work?

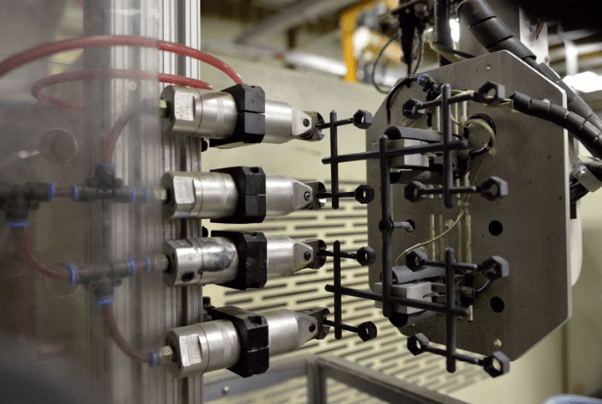

The manufacturing sector is vastly expanding, and more and more production ideas are coming up. So how does the plastic injection molding work? Usually, it all starts with the thermoplastic injection coupled with the injection process straight from the photo lab. This is a procedure that involves an aluminum mold.

The material used in this case is heated efficiently- far much more than basic steel. Therefore, it transfers a lot of heat more than how steel how can do it. It also does not need any form of cooling channels. This implies that the whole process is time-saving, even though cooling needs to be applied in order to monitor pressure.

Final Thoughts

Conclusively, the resin pallets will be loaded into a unique barrel where they can be melted and then compressed. They will then be injected into the runner system of the mold. In this case, resin, hot as it is, will be shot into the cavity of the mold via the openings.

Technically, the ejector at the machine will facilitate the removal of tough parts from the inside of the mold. And when completely run, the parts will be boxed and then shipped as the procedure demands. Being experts in this field, we can easily supply brass part inserts if you make your order into a particular specification. For most of your customers, this just implies that all too often, there is no requirement for additional purchasing and collaborating with the suppliers because we handle all the tasks for them. Our involvement in the processes eliminates the huge risks of delay straight from the other suppliers who can interfere with the process.