There is nothing easy about starting a new project that includes creating a new part or an entire product, even for the most experienced engineers and entrepreneurs. Sometimes, even creating a tiny bolt can take hours of meticulous planning, calculating, and drawing.

On top of that, you have to figure out the actual forming process that will lead to the creation of the physical part.

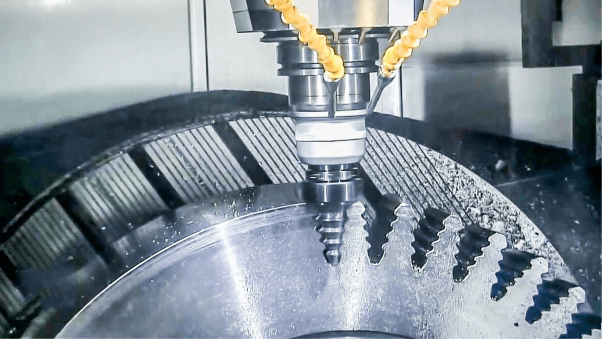

Very often, that choice is between a CNC milling service and 3D printing. Here are some of the most important factors to consider when choosing between the two technologies.

Dimensional Accuracy

This is one of the most important factors to consider when choosing the best-suited technology. CNC machines can achieve accuracy of up to 0.01 inches, while the tolerance can range up to 0.005 in.

On the other hand, 3D printer accuracy can vary from printer to printer, as well as on the used technology. For example, a desktop FDM 3D printer features an accuracy of 0.5mm, while with the industrial ones, it can be as much as 0.2mm.

If it is an SLS 3D printer, the accuracy will be in the range of +/- 0.3mm. If it is a metal 3D printer, the accuracy will likely be +/- 0.1 mm.

Design Complexity

Some parts cannot be manufactured with a CNC milling machine. If the part includes complex internal parts such as overhangs, then your only option can easily be 3D printing.

Production Cost

In both cases, the production cost is determined by factors such as the volume of the object, the material used, and the complexity.

In the case of 3D printing, you pay for the used material and the final volume of the object.

If you opt for CNC milling, then keep in mind that the smaller the object, the less cost-effective it is. In most cases, it’s way more cost-effective to use CNC milling for a larger object.

Loading

Structural parts that will be exposed to continuous physical loads are mainly made with CNC machining. 3D printing is preferred for creating non-structural parts. However, by adding some fiber reinforcement, the part can gain significant strength improvement.

The Greener Option

From this perspective, a 3D printer is the greener option because it uses less energy, and practically there isn’t any waste. On average, CNC machines tend to draw way more electricity because of the cutting tools, and after the process is completed, there can be plenty of waste.

In Conclusion

The simple truth is that 3D printing is not cost-effective for larger orders. That’s not the case with CNC milling. At the same time, sometimes CNC can’t produce certain complex products, while a 3D printer can.

So it is fair to say that each technology has its advantages, as well as limitations. Understanding them is the most important step in choosing the right technology.