The LED printers contain similar characteristics to the laser printers. Identical to those of the laser, the LED printers contain light-emitting features.

Despite their similarities, there exist some differences in both printers. 80% of users of both printers have ranked the LED printers above the laser printers.

Advantages of LED Printer usage

As aforementioned laser printers are great printers to be used. However, the LED printers are more often preferred.

Details on why the LED printers come out the top would be highlighted on this page.

1. Dependability

Firstly, the LED printers are more dependable. This is because LED printers contain few constructed moving parts. As such is prone to fewer mistakes and omissions.

2. Usage

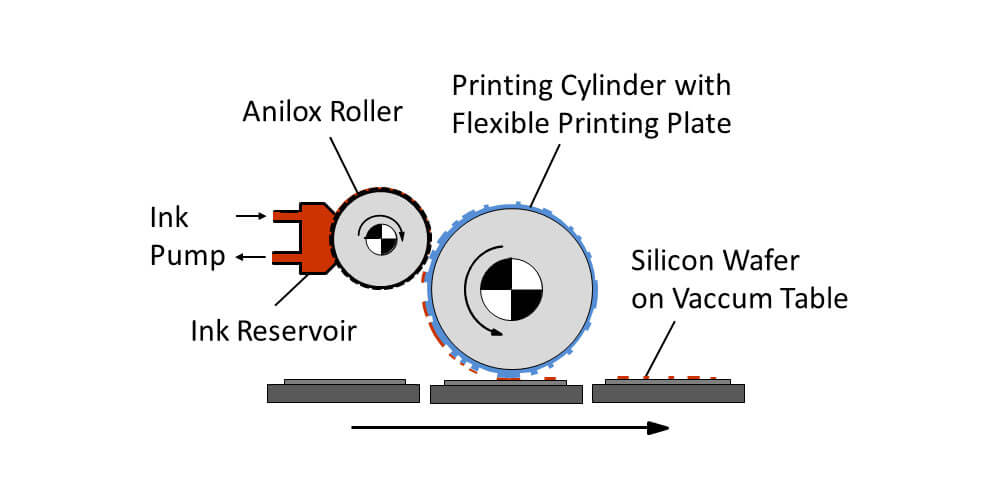

The usage of LED printers is more straightforward than those of laser printers?

This is due to the mode of production of laser printers. During its production stage, multiple cylinders and lenses were inserted. In line with that, these lenses and cylinders have to be in perfect order for quality printouts to be made.

However, when taking a look at the LED printers, only a very few amounts of cylinders were inserted. At such less concentration from users is required.

In turn, less concentration from the user gives room to less assembling while a printout session underway.

3. It cuts cost

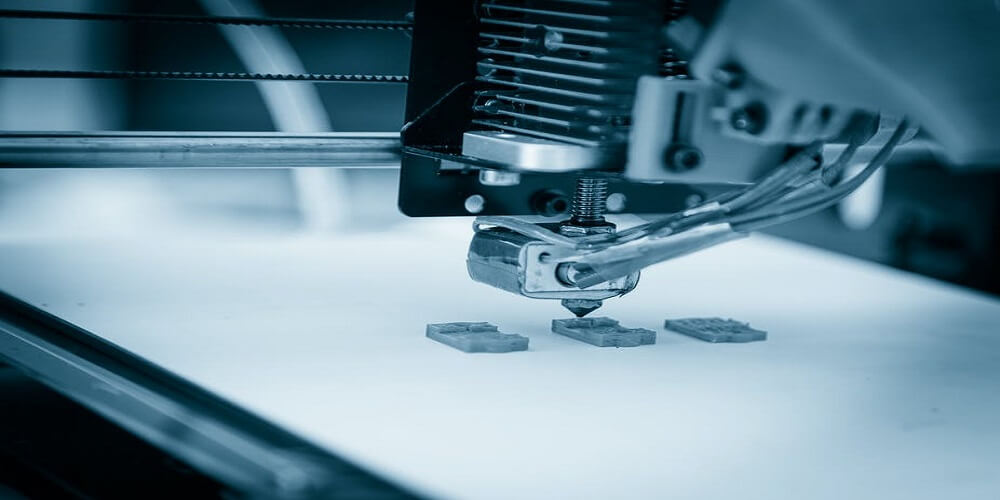

Here’s one problem with the more conventional machines used in production. You have to use various machines to achieve what the 3D printer can do. Thus, you end up spending way more than you should produce a particular producer.

However, with 3D LED printers, you get all you need in one go. That makes the cost of operations better. Here’s something else that they do.

4. Affordability

In addition to cutting down, they are also quite affordable when compared with the conventional means of production. With those machines, you get to spend a ton getting everything you need.

While those machines might seem cheaper individually, they are quite expensive when brought together. However, 3D printers offer you the chance to have everything you need in one place.

That makes everything so much easier.

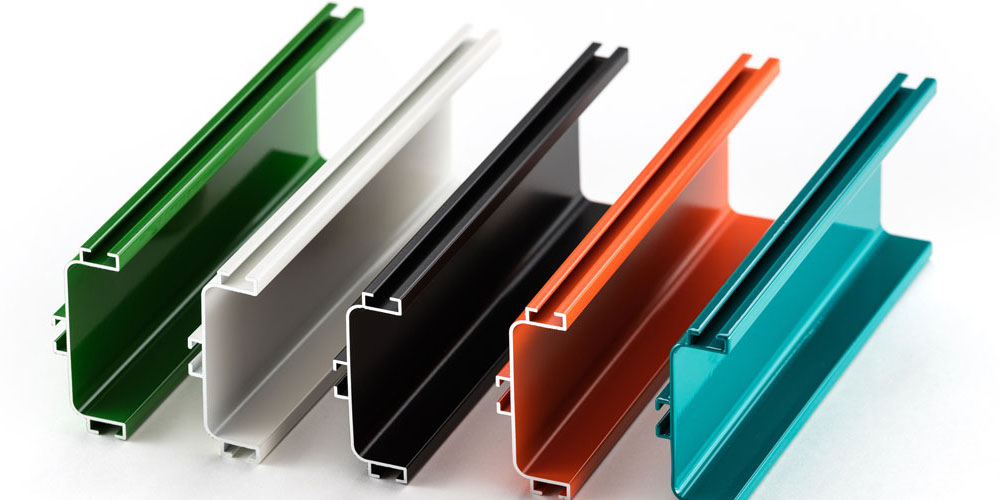

5. Modern Touch

Face it. You definitely don’t want to be left behind in our world. Every day, the world keeps on pushing technological advancements to new heights.

If you have a company or plan to produce a prototype, then losing the battle of 3D printers is simply not the way forward. It will hurt the image of your company in the long run.

So, what should you do now?

LED 3D printers are one of the best things yet. So, if you have decided to get one, make sure that you do it right. Do all the research needed and know more about the product before you actually go for it.

It will help you to make the right purchase.

Conclusion

So there you have it! LED 3D printers are here to stay. They can have a tremendous impact on your company or business. So, if you can buy one, don’t hesitate. It’s a great piece of business.