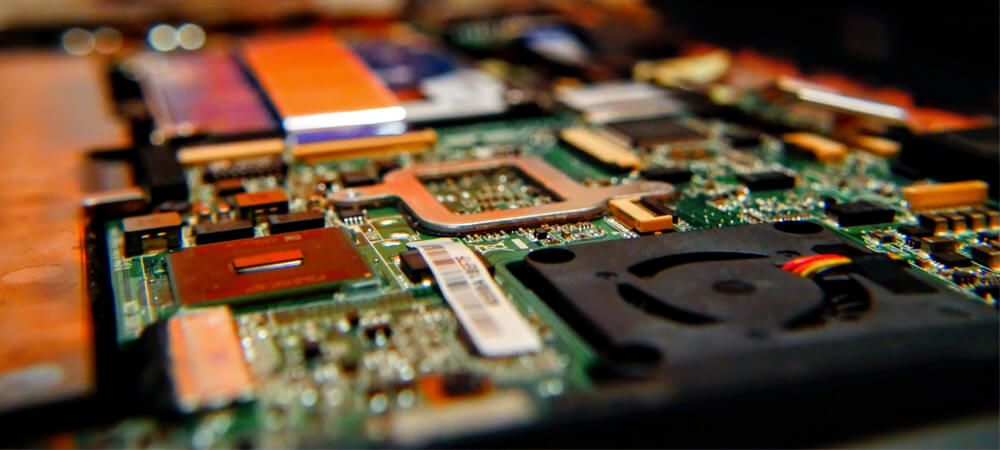

Printed circuit boards have proven to be essential to us. PCBs have passive and active components that are linked by traces on the board. It is possible to place may circuits on one board when small-sized components are readily available. Printed circuit boards perform necessary actions in the electronic devices; hence a lot of care should be taken when assembling them. Printed Circuit Board manufacturers have branched into different industries, such as; the medical industry, Aerospace, Automotive, New energy, Digital communications, and consumer electronics.

Types of printed circuit boards

- Single-sided PCBs

- Double-sided PCBs

- Multilayer PCBs

- Rigid PCBs

- Flex PCBs

- Rigid-flex PCBs

What are the benefits associated with the use of these printed circuit boards?

Reduced gadget size

What a printed circuit board does is offer a platform to place a large number of circuits provided you have the necessary components. Instead of using wires, the components are connected using a single track of copper wire. Small components are used to reduce the size of the circuit further, meaning that a small circuit can perform multiple actions and thus reduce the size of the gadget at hand. Imagine how big our mobile phones would be if we did not have printed circuit boards.

Easy repairing

With a printed circuit board, you can easily spot failures in the components and repair them. Some gadgets we use do not require a lot of rocket science to repair thanks to printed circuit boards. Some components are easily accessible, and you can get your device working again in no time.

Time-saving

The traditional way of connecting components in a circuit with wires takes up a lot of time compared to using a printed circuit board. The boards are made with high precision, ensuring that their quality is not compromised. This means that cases of failure are minimal, and you are guaranteed a smooth run.

Components are firmly attached to the board

The components in a circuit board are firmly attached to the board by flux. This means that movements cannot tamper with the natural setting of the components. It would be an awkward situation if you suddenly dropped your phone and a capacitor comes out of it

Reduction in the cases of short circuits

When a printed circuit board is assembled, all the connections are made through copper tracks, and no loose connections are left on the board. This makes it rare for short circuit accidents to happen.

Reduced noise

An adequately made printed circuit board emits little or no noise. With a PCB fabrication

, your device should run smoothly and quietly.

Technological advancements are giving rise to new things every day. Big industries are growing fast because of the use of printed circuit boards. The advantages associated with using PBCs are countless. We have gradually managed to change the size of our devices with the help of PBCs. The Automotive industry is rapidly growing after embracing the use of printed circuit boards. Since these boards handle essential tasks for us, there is the need to pick the best manufacturers.