There are two main types of die forging. The two main types include closed and open die forging. The only difference between the two types of die forging is only the die plates. Furthermore, both processes are used for deforming and shaping metals. The die forging processes can be used in several sectors of the economy to attain quality parts. You can go to this website to learn more about the different sectors where die forging is applicable. In addition to the fact that die forging can be used to attain quality parts, there are several other benefits. Therefore, this article will update you on the benefits of die forging.

8 benefits of die forging

1. Cost-effective

Die forging allows for the production of vast volumes. Vast volume production means that little time is used in the production process. Therefore, more parts produced in a little time suggest that less money is used in the production process. Also, high production volumes can signify high returns in the end.

2. Produce complex shapes

The die forging process allows for the production of both simple and complex shapes. The fact that the die forging process can produce all shapes means that it can save you money since you will not need to use different machines to forge different shapes. Also, the fact that die forging can lead to the production of complex parts ensures that one can enjoy the benefit of design flexibility.

3. High precision levels

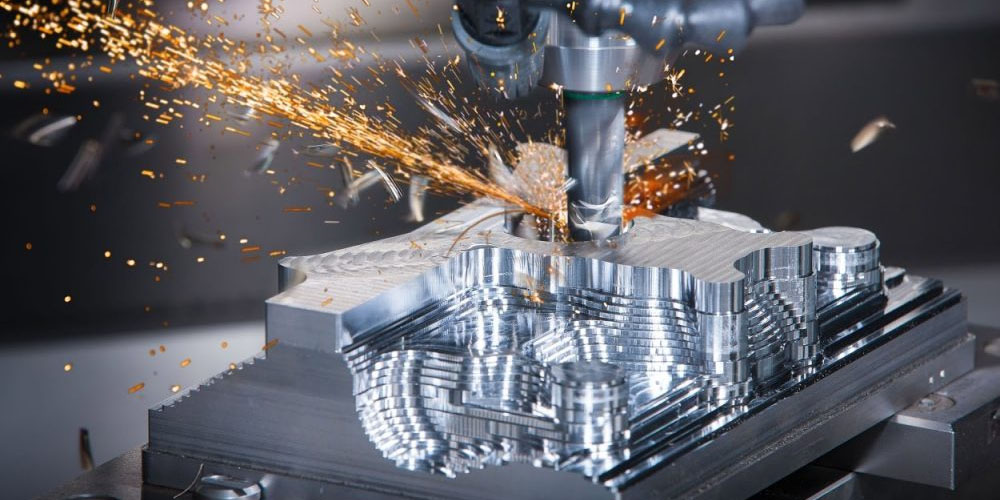

The die forging process is automated therefore able to produce high precision parts. Furthermore, the précised parts are produced to match your exact specifications. Thus, the die forging process, especially the closed die forging process, ensures high-quality parts.

4. Strong parts

Die forging requires the heating of metals in high temperatures to produce both intricate and simple parts. The various processes used in die forging ensure that the parts made are tough. Thus the tough parts have few weaknesses, therefore, cannot easily break or crack.

5. Wide range of part size

Die forging allows for the forging of parts of different sizes. Therefore, die forging allows for no limitation when it comes to size. It can forge both small and big size parts.

6. It can be used on tough metals

One of the best benefits of die forging is that it can be used on tough metals like iron. Other techniques like cold forging cannot be used on tough metals like iron. Thus, the die forging heating processes ensure that iron can be made into an easy form to forge.

7. Good surface quality

The die forging process ensures that the parts have good quality surfaces. The good quality surfaces offer room for quality finishing.

8. Durable parts

Parts produced by the hot forging process are long-lasting. Therefore, die forging ensures that parts produced are not faulty.

Conclusion

The die forging process is essential in creating quality and durable parts. Any mistakes in the forging process can bring unimaginable consequences in some sectors, such as the automobile sector. Thus, the best benefit of die forging is that it allows for the production of high précised parts with no errors.